Product Features

-

Higher Reliability and Stability

Higher Reliability and StabilityCOB LED fine-pitch display technology offers higher reliability and stability, significantly reducing failure rates during use to less than 10 PPM.

-

Exceptional Impact Resistance & Durability

Exceptional Impact Resistance & DurabilityCOB packaged lamp beads are encapsulated on the PCB board with epoxy resin. The epoxy resin has extremely strong affinity with the PCB board, resulting in superior physical impact resistance—more than 5 times that of SMD. For example, even if a 10kg iron ball falls onto the surface from a height of 1m, it will not be damaged.

-

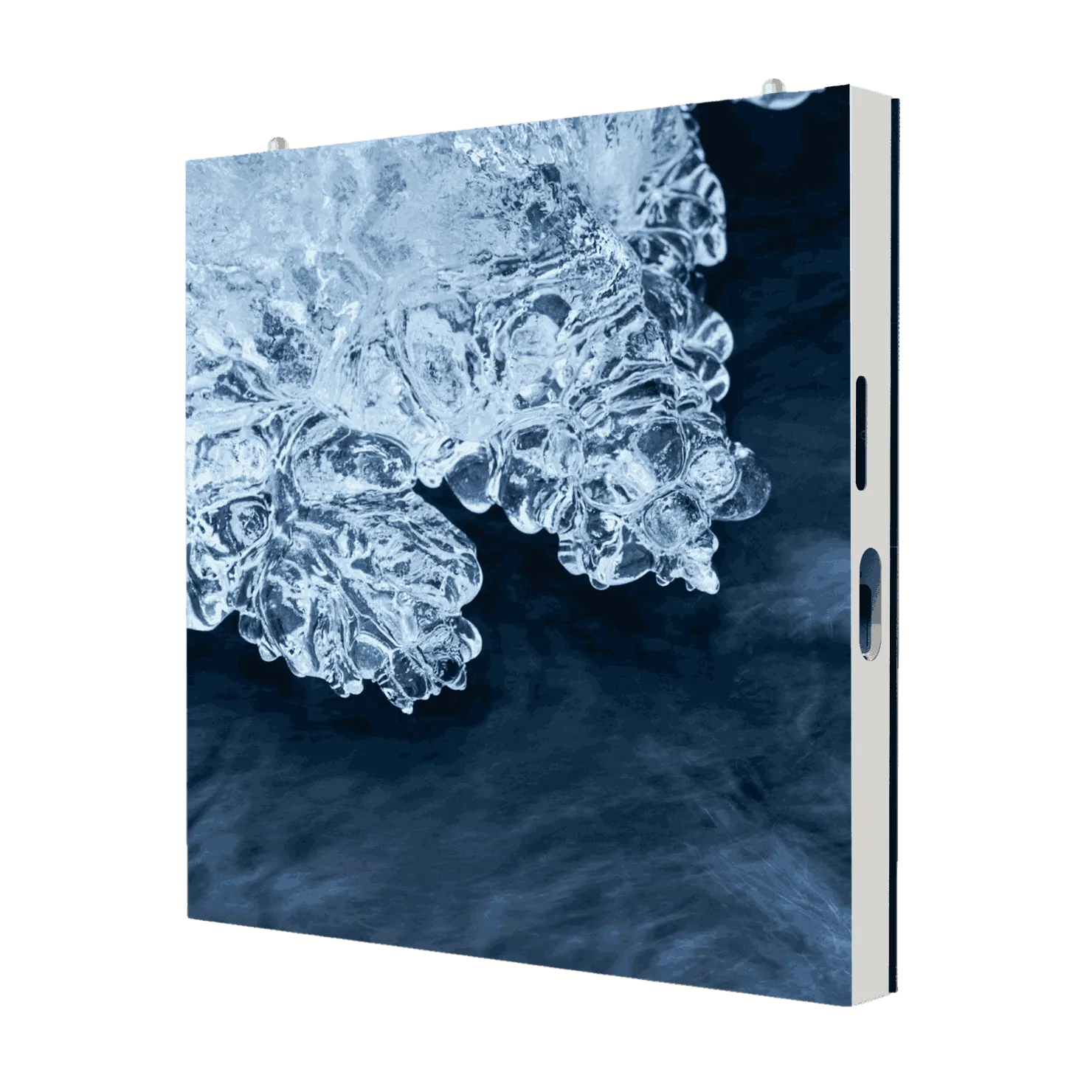

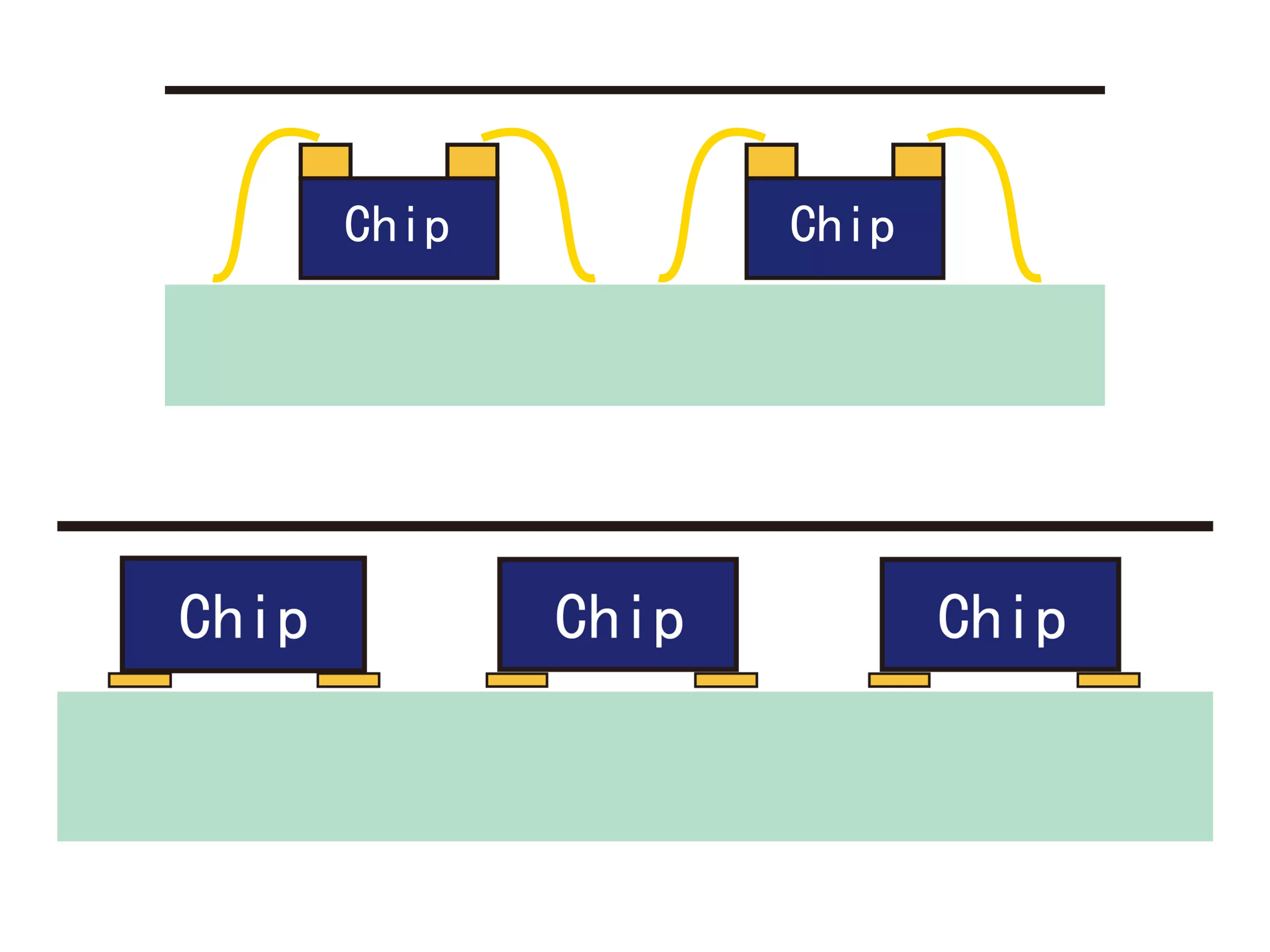

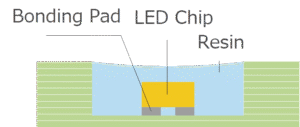

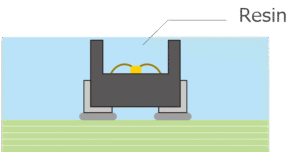

Flip Chip COB

Flip Chip COBEbony series are supported by flip - chip COB, ensuring lower power dissipation and more stable qualities.

-

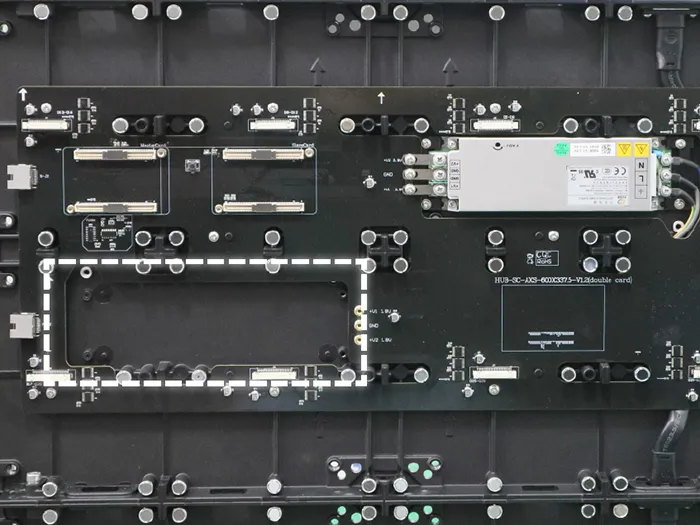

Power & Data Redundancy

Power & Data RedundancySpace is reserved for redundancy system in case of any high standard situations.

-

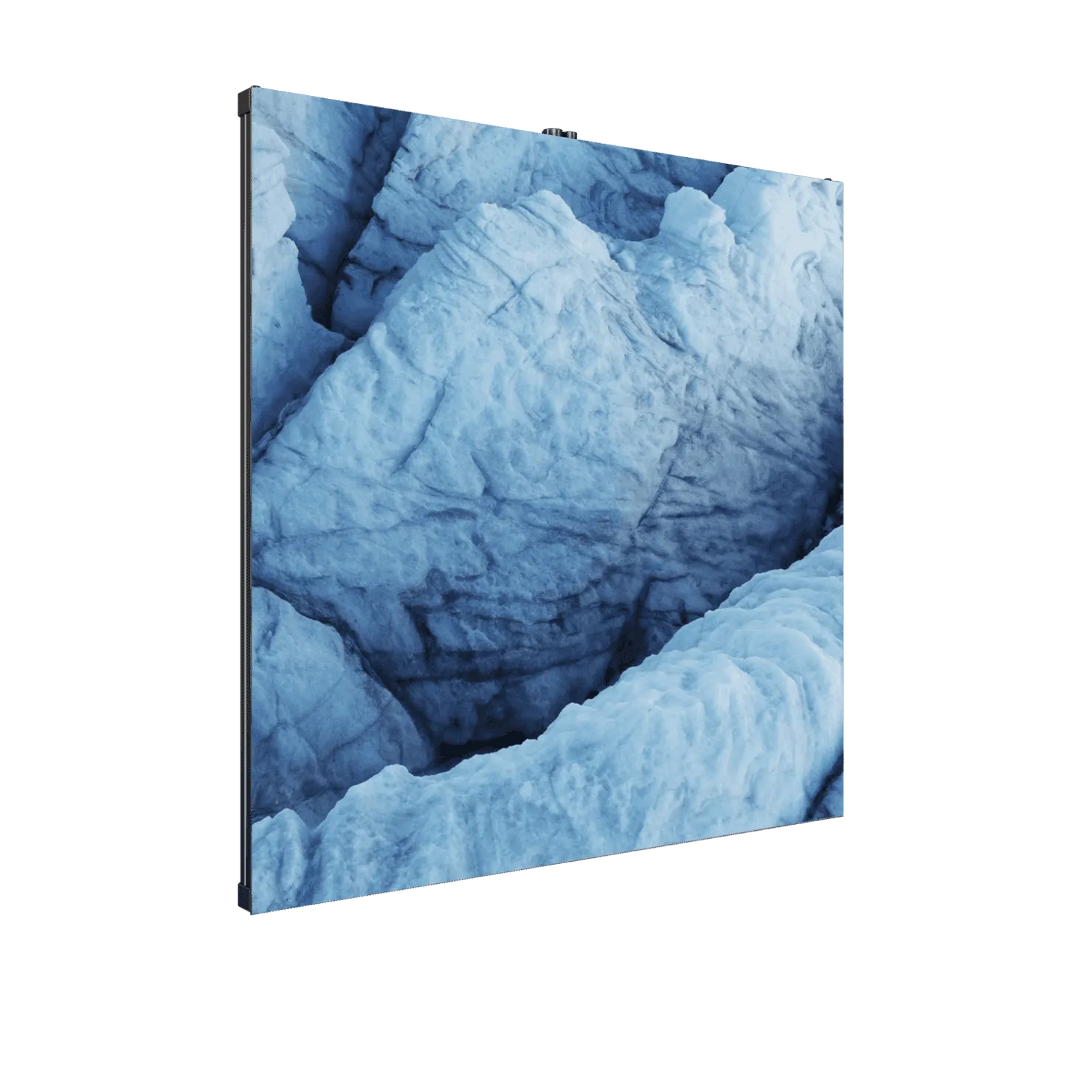

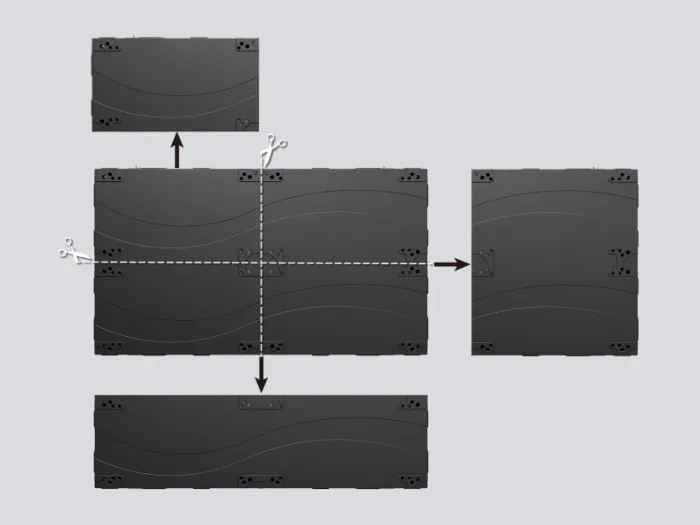

Multi Cutting for multi Splicing

Multi Cutting for multi SplicingVarious dimensions have been meticulously tailored to accommodate more aspect ratios for multifarious scenarios.

-

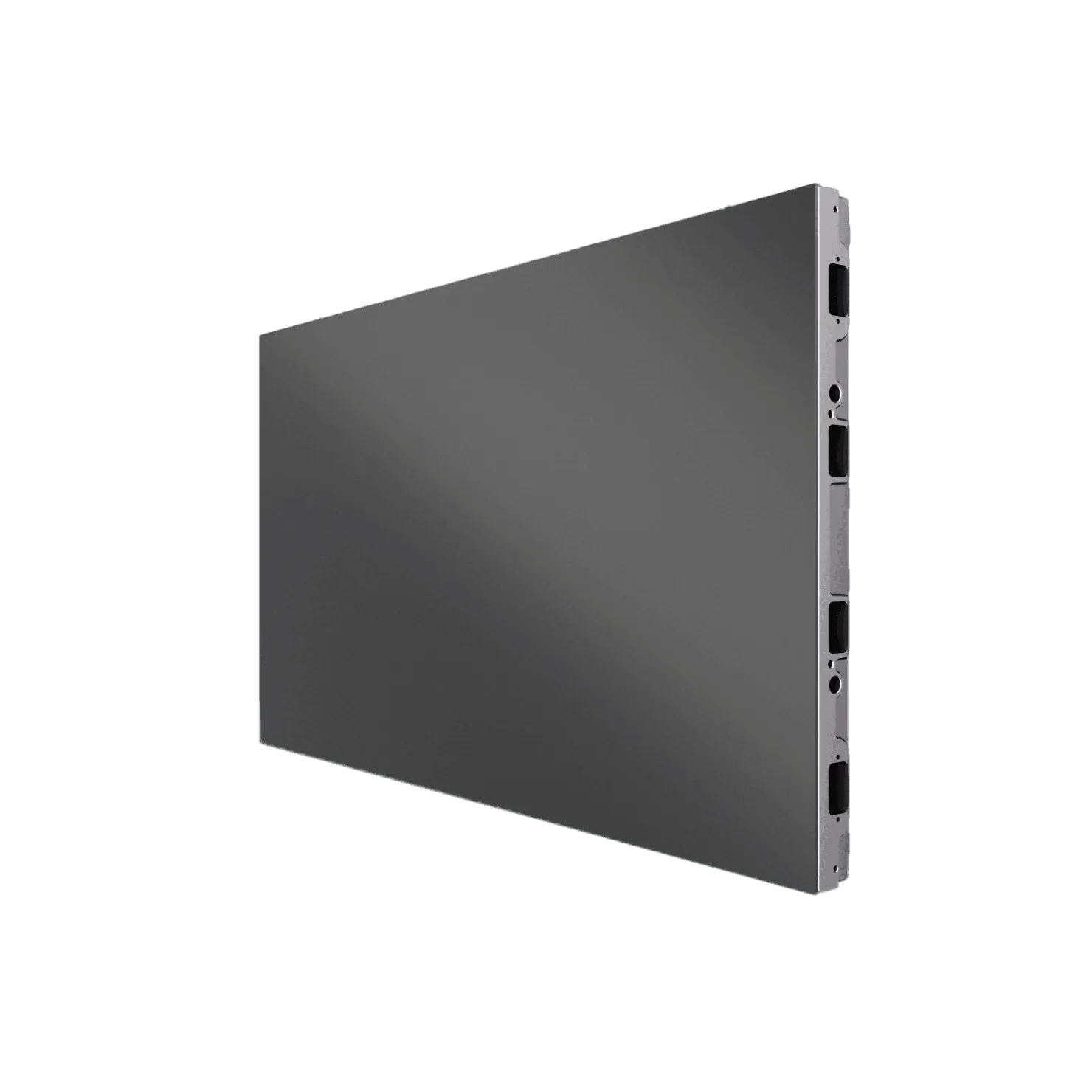

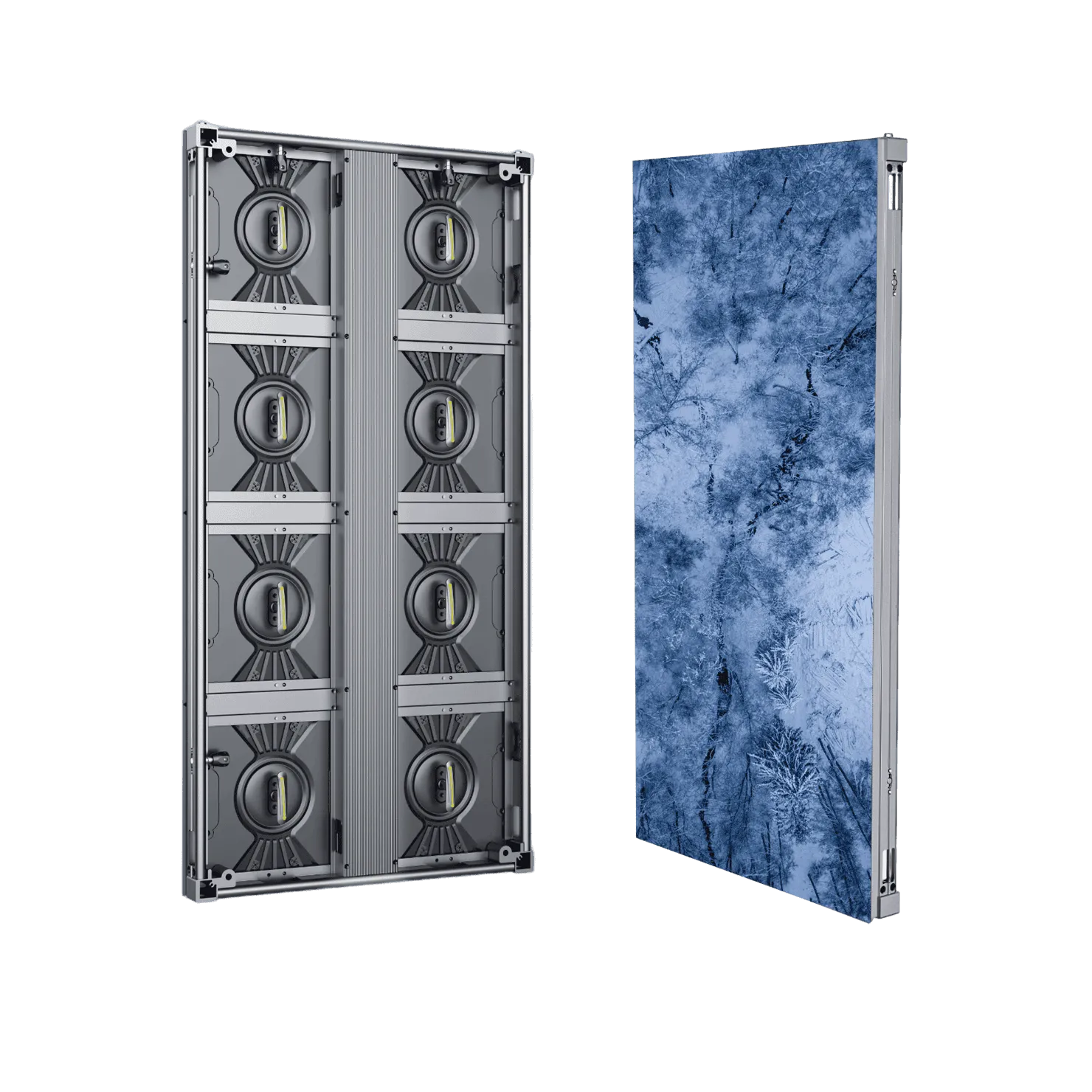

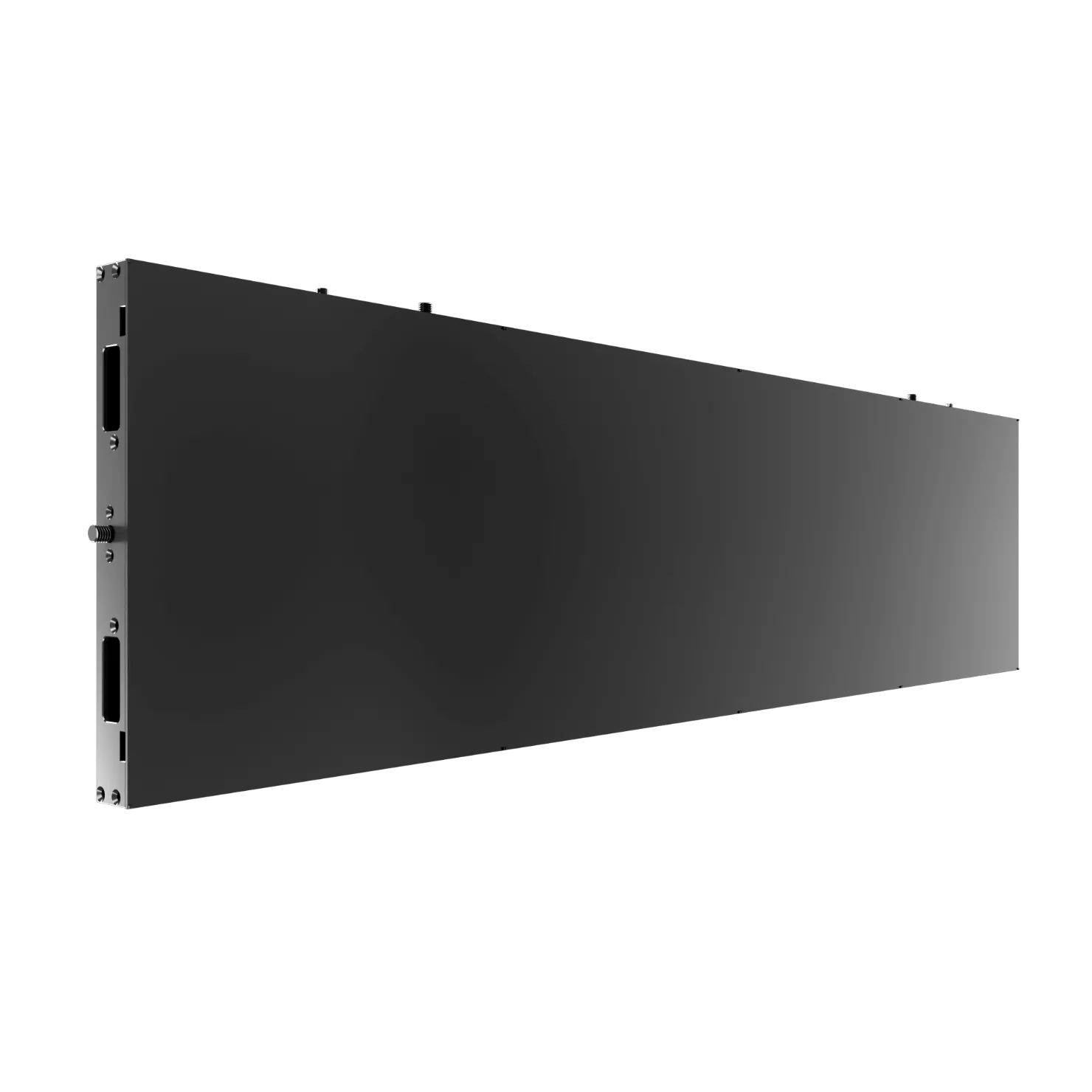

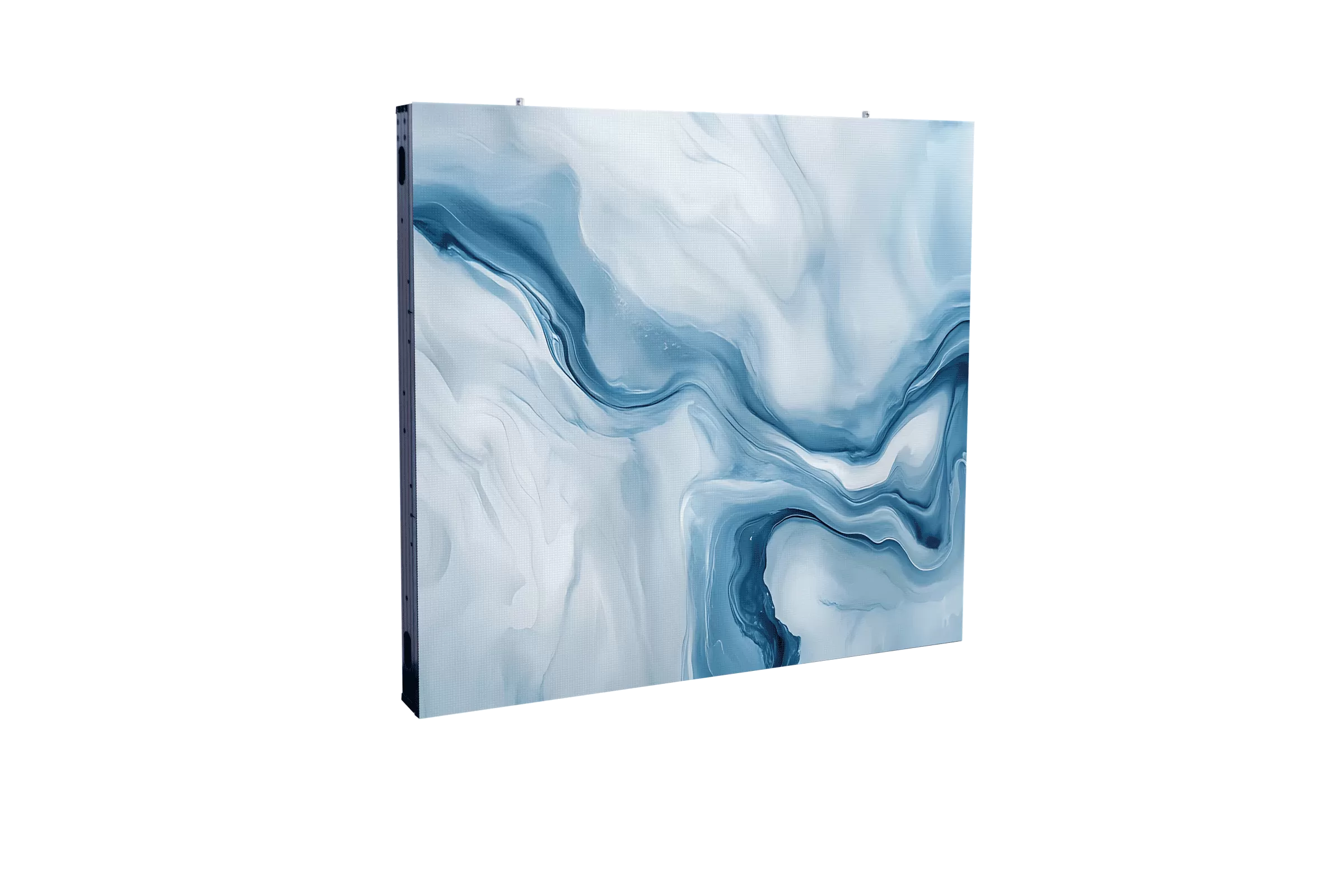

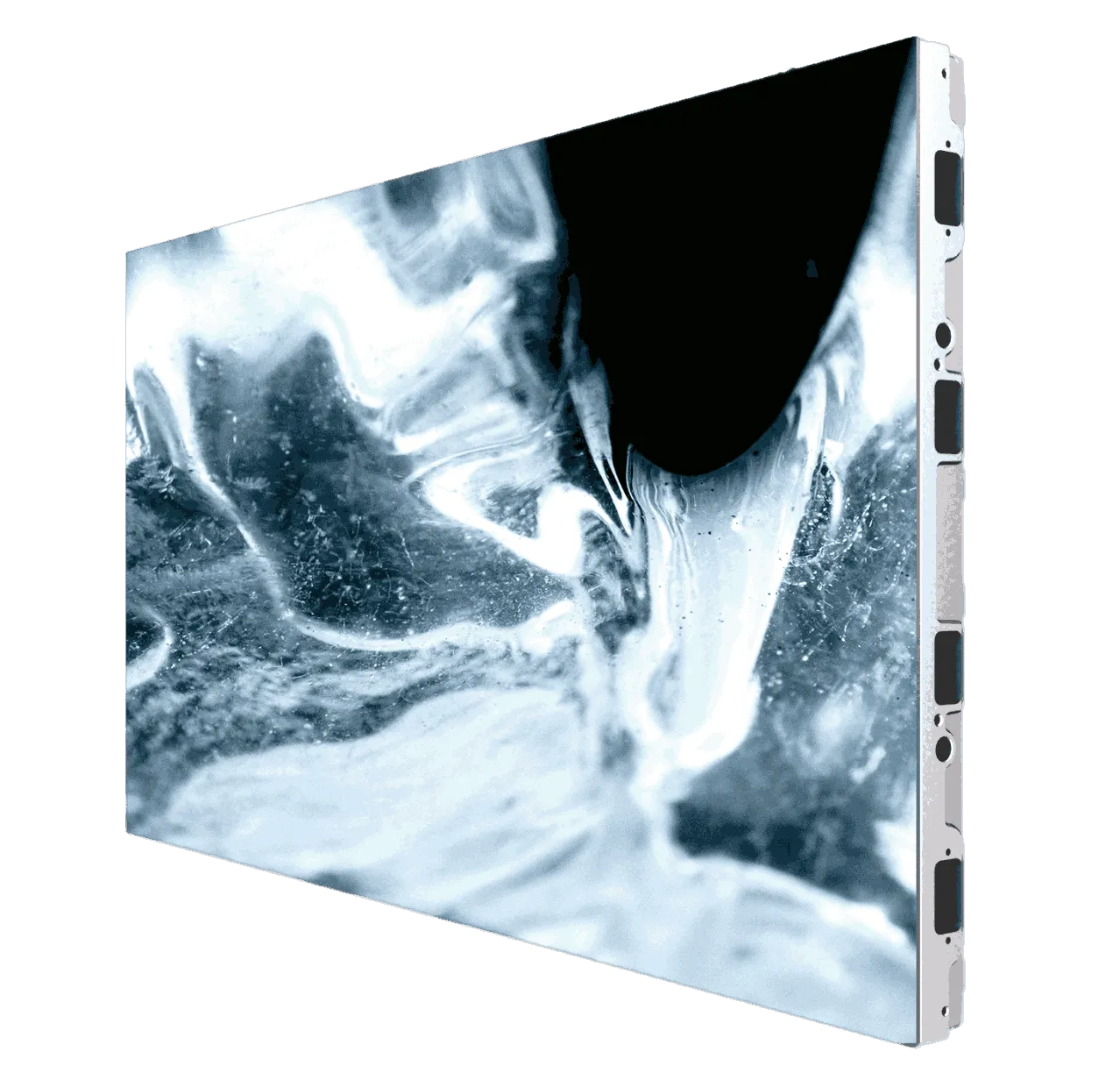

Extraordinary Versatility

Extraordinary Versatility1. Magnetic module allows fully front maintenance.

2. Front installation is available due to the reserved screw hole.

3. Ultra thin and light-weight cabinet match up with more application scenarios.

4. Aiming to protect the operator from cut and improve the appearance, the Ebony panel is processed with edge-rounding and electrophoresis. -

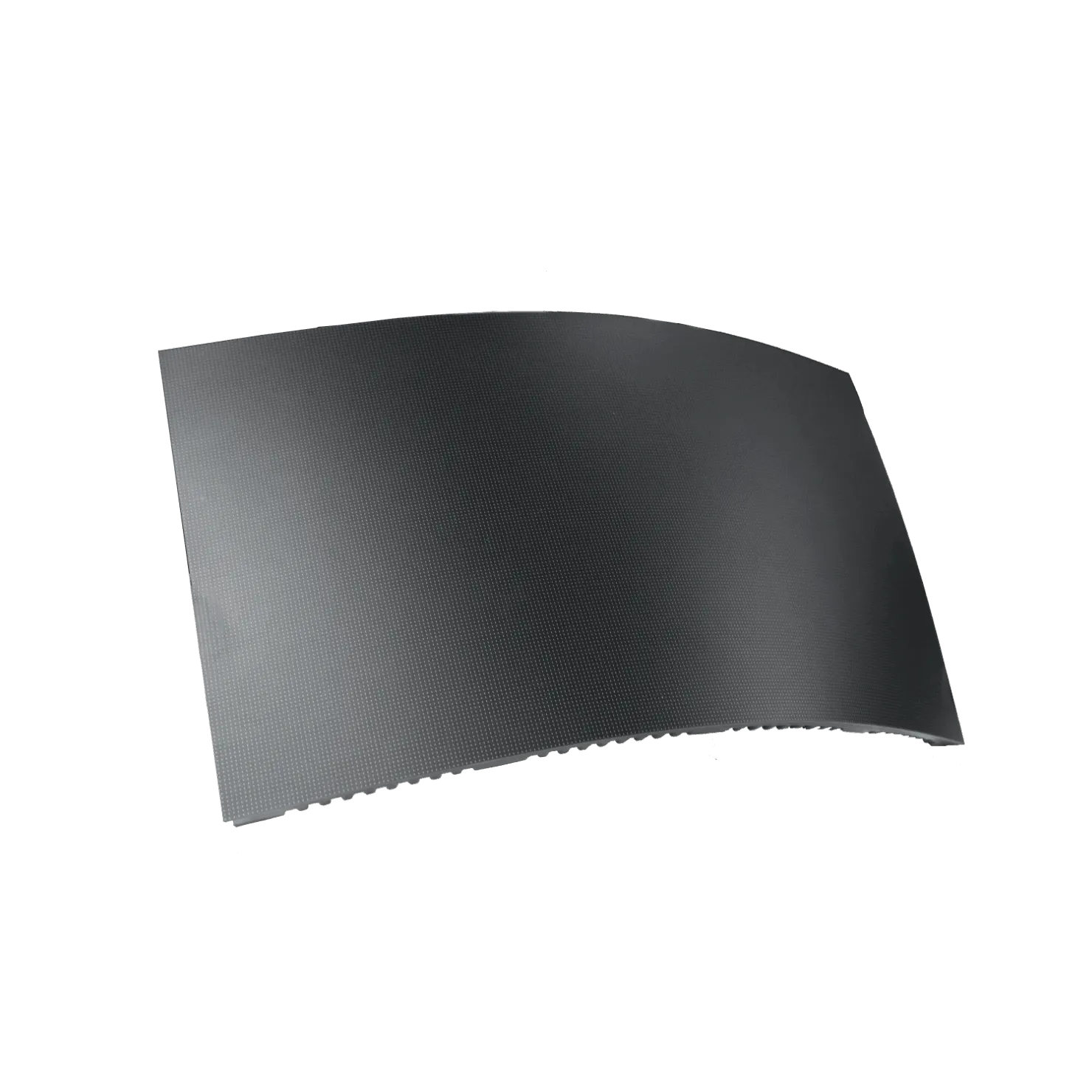

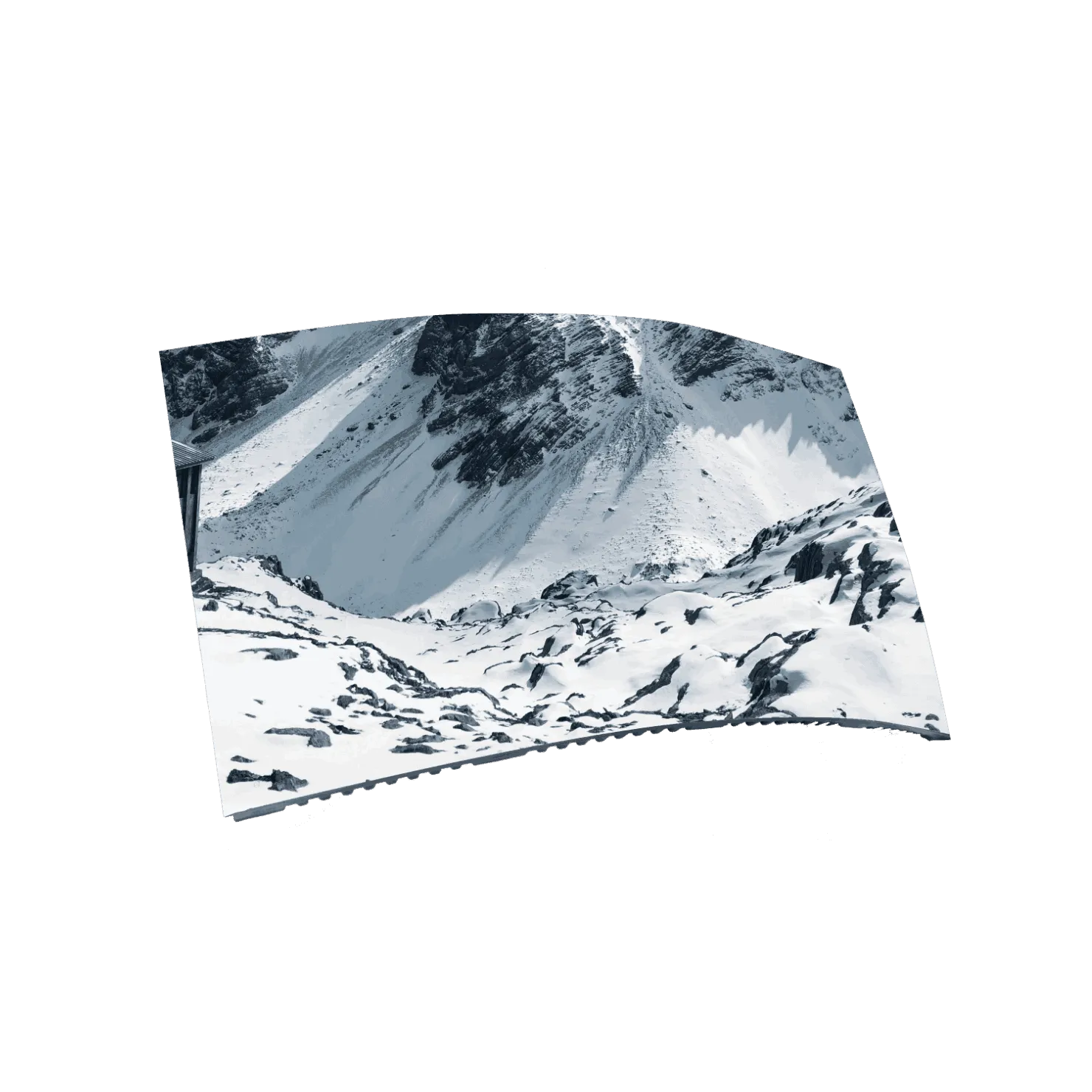

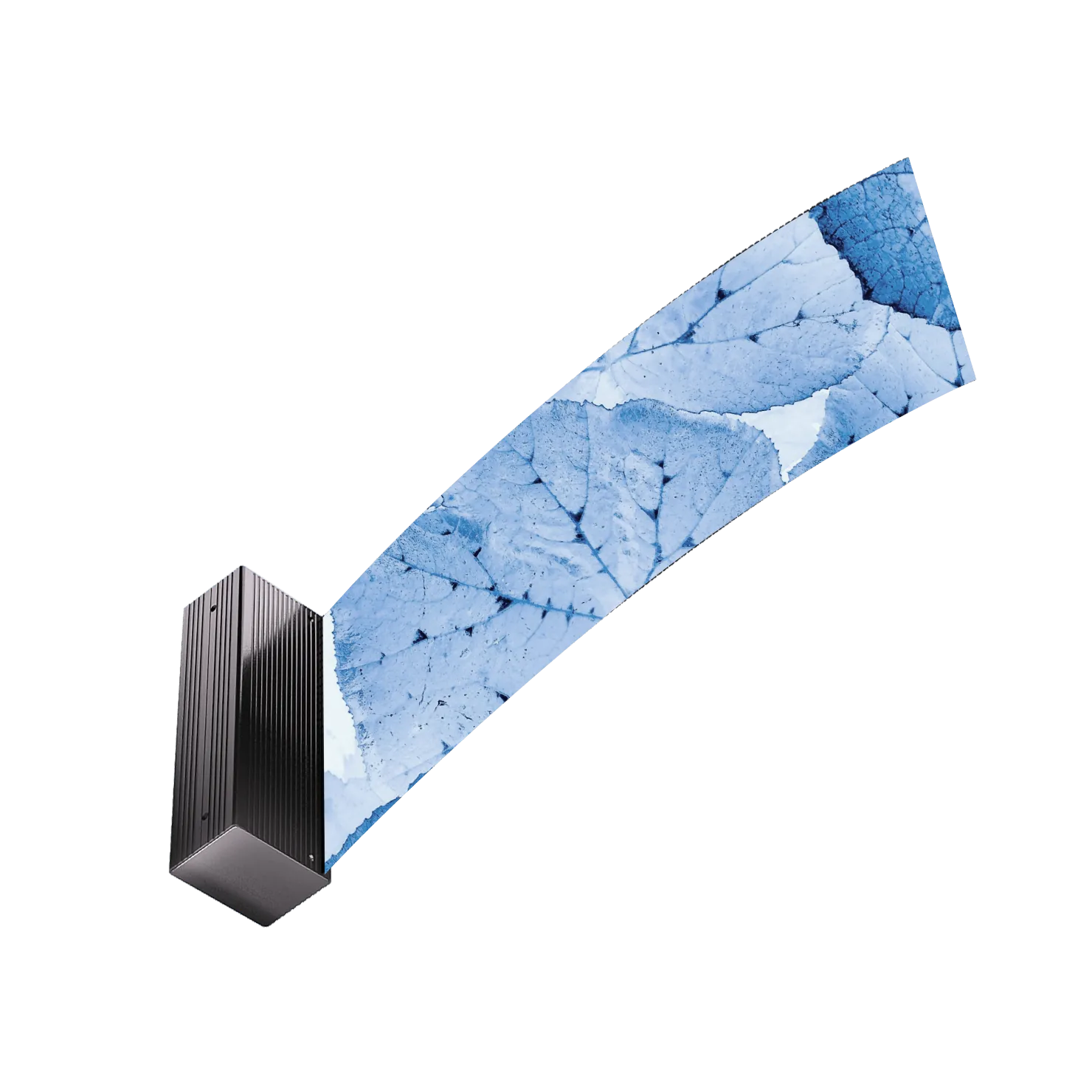

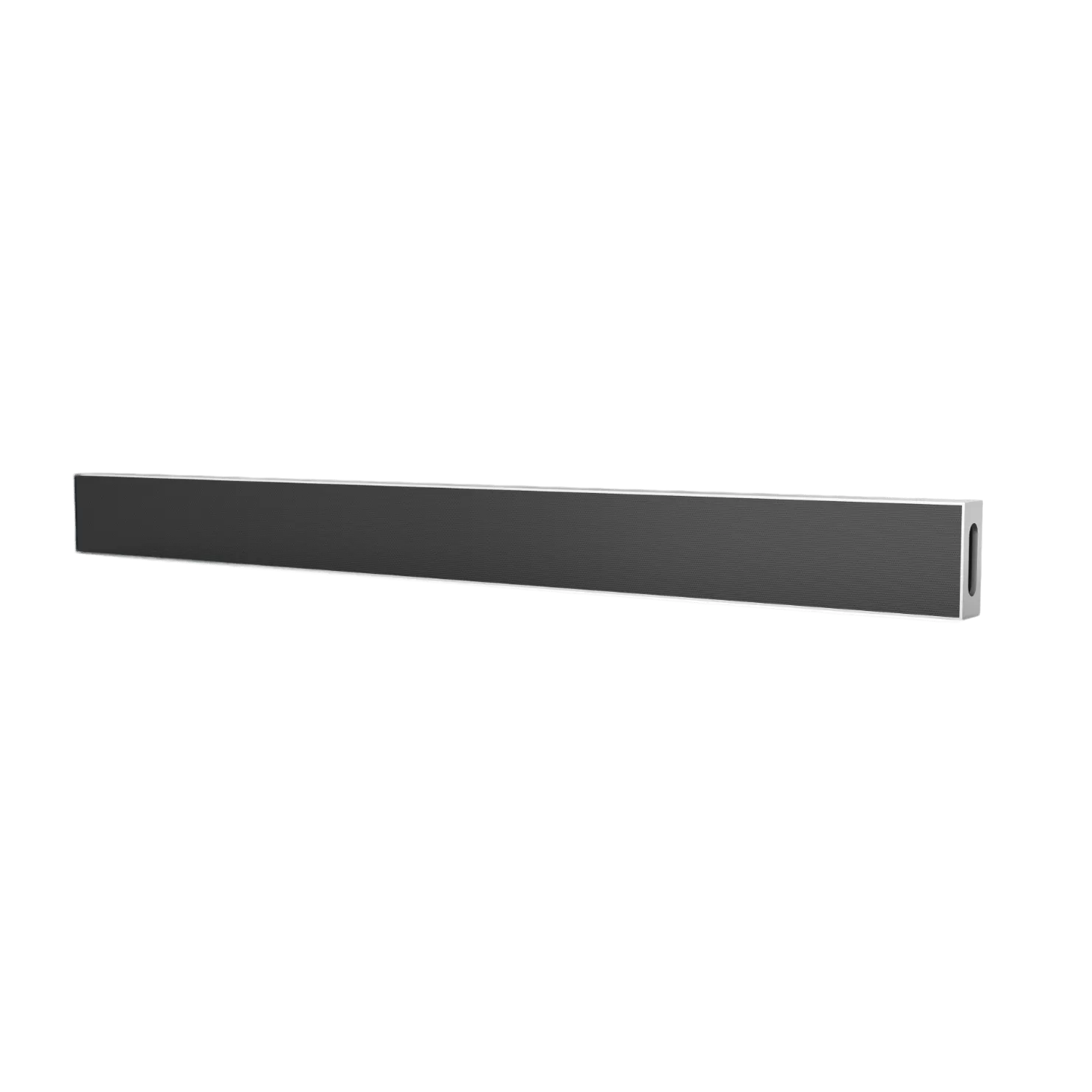

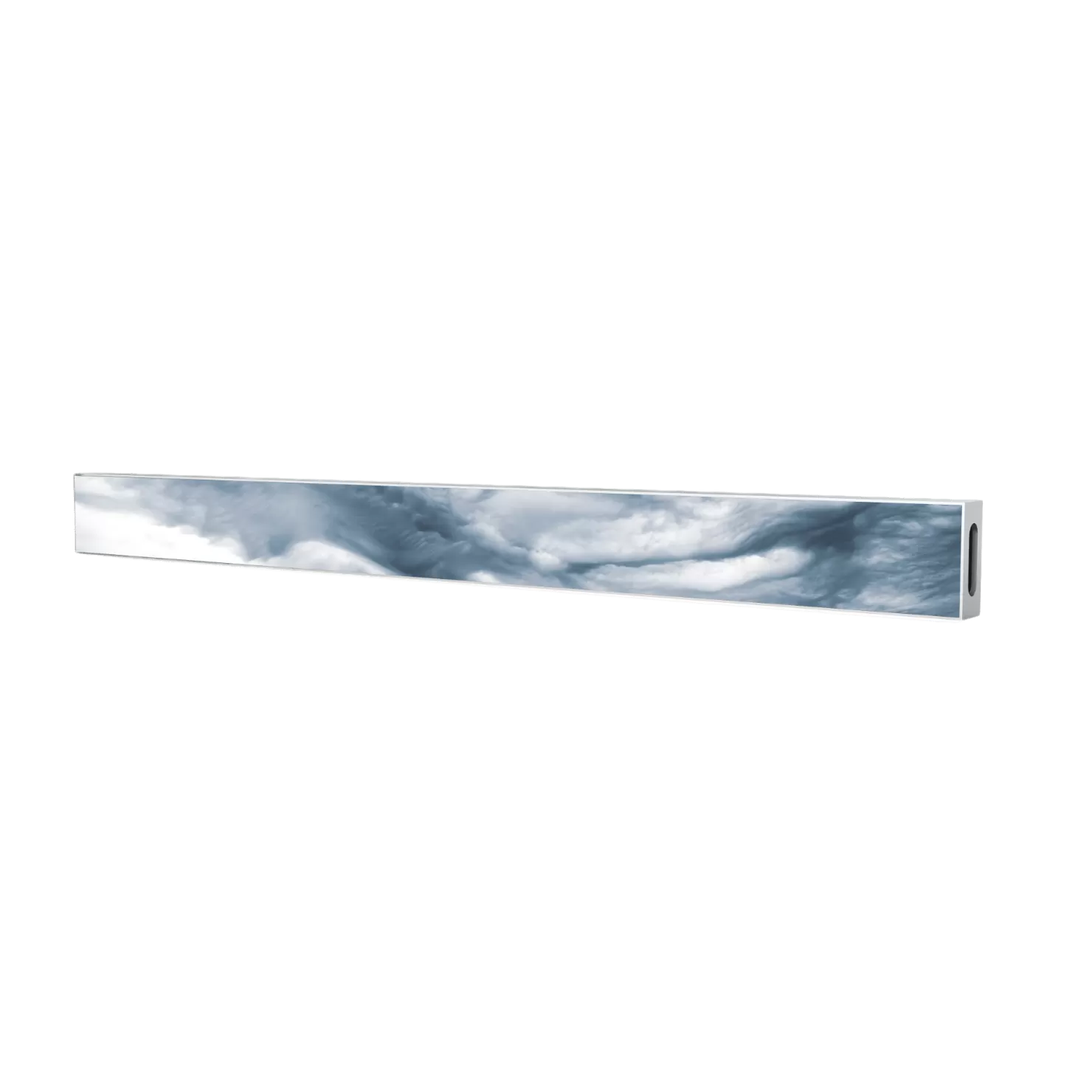

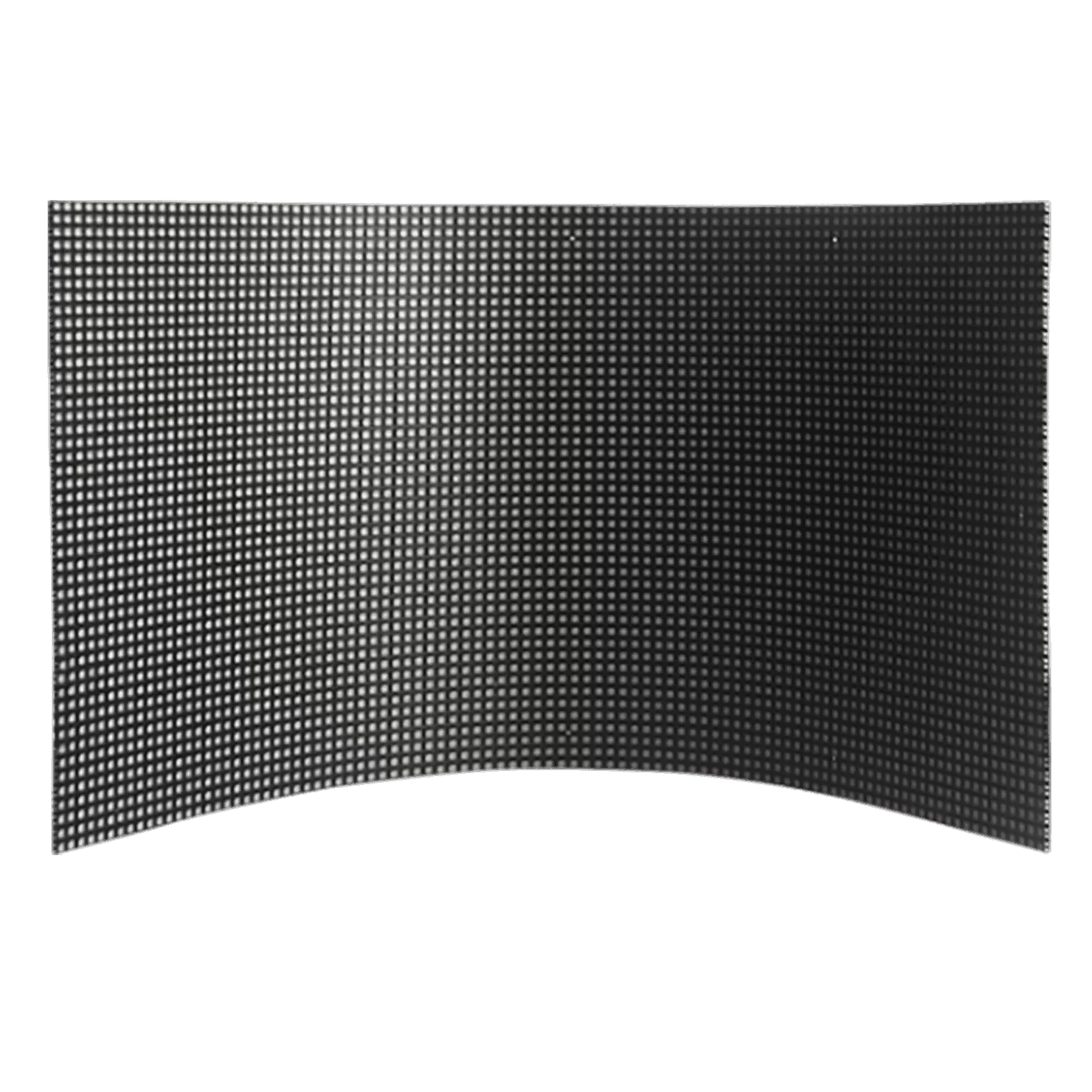

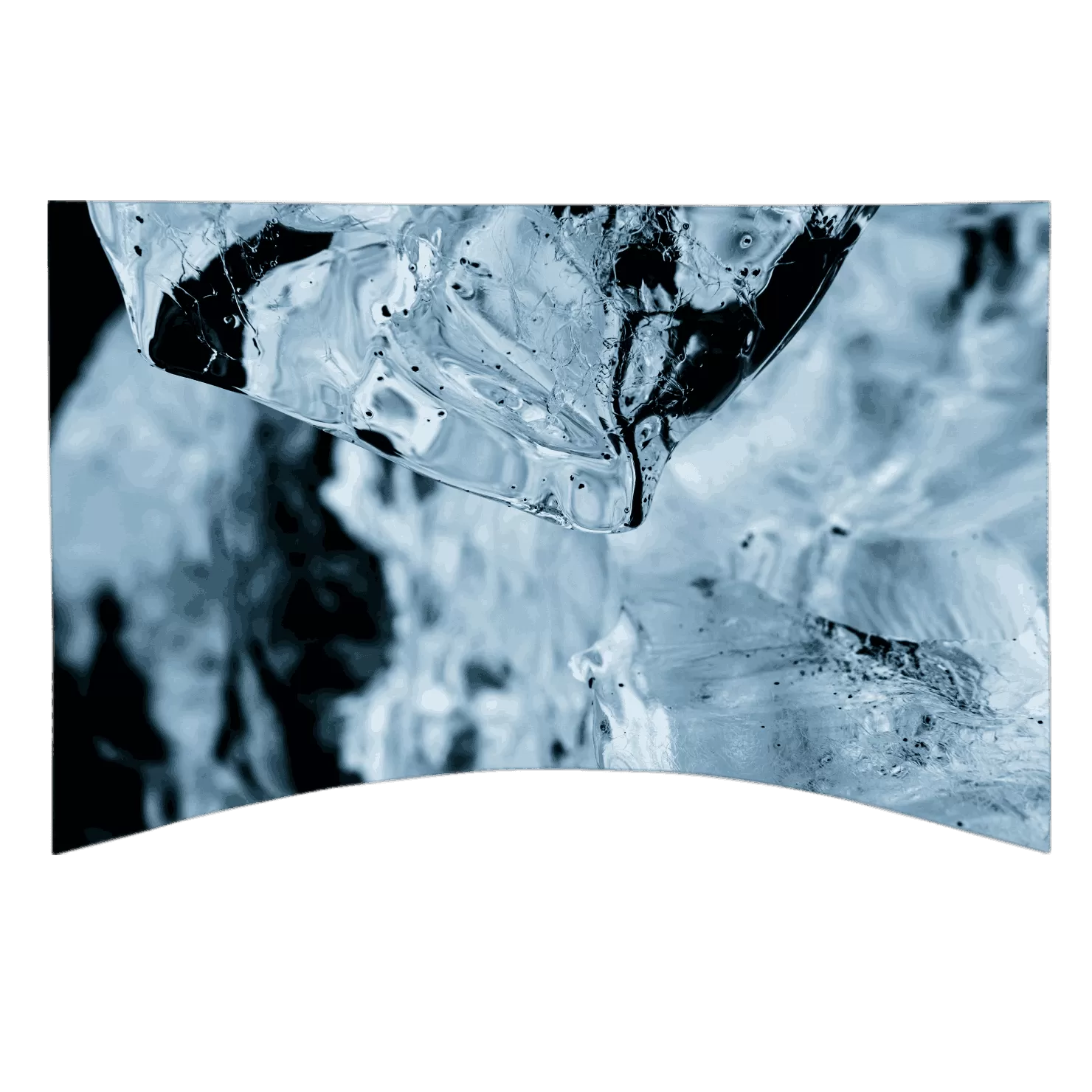

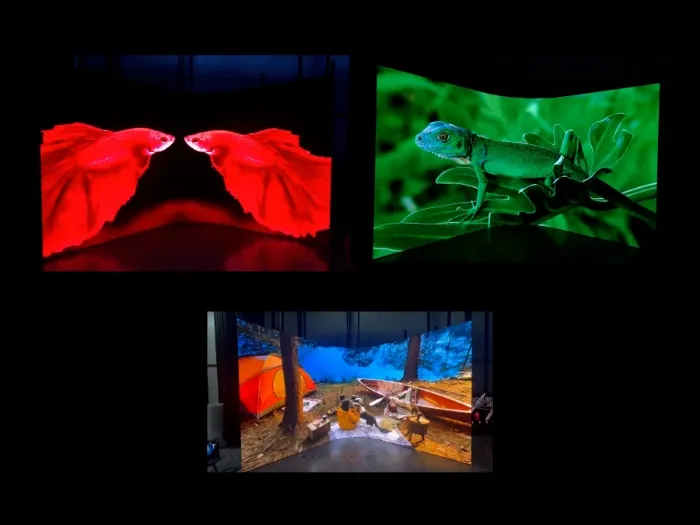

Soft COB for Options

Soft COB for OptionsWe have multitudinous solution of COB family. Soft COB module helps us to achieve more shapes of the display like concave, convex, multi-shape connection, etc. And the key point is we could use them all with the same COB stuff to avoid the discrepancy of visual sense.

-

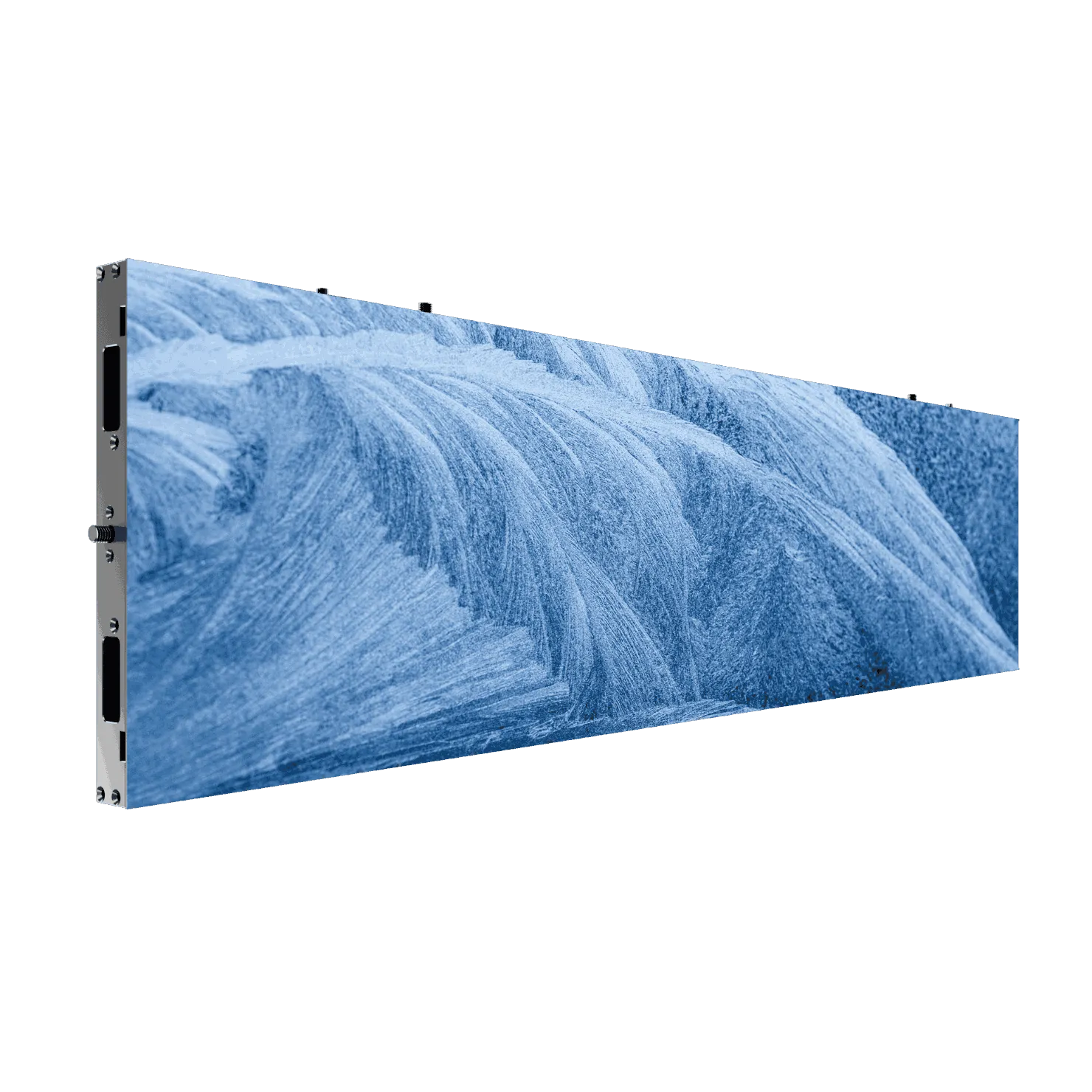

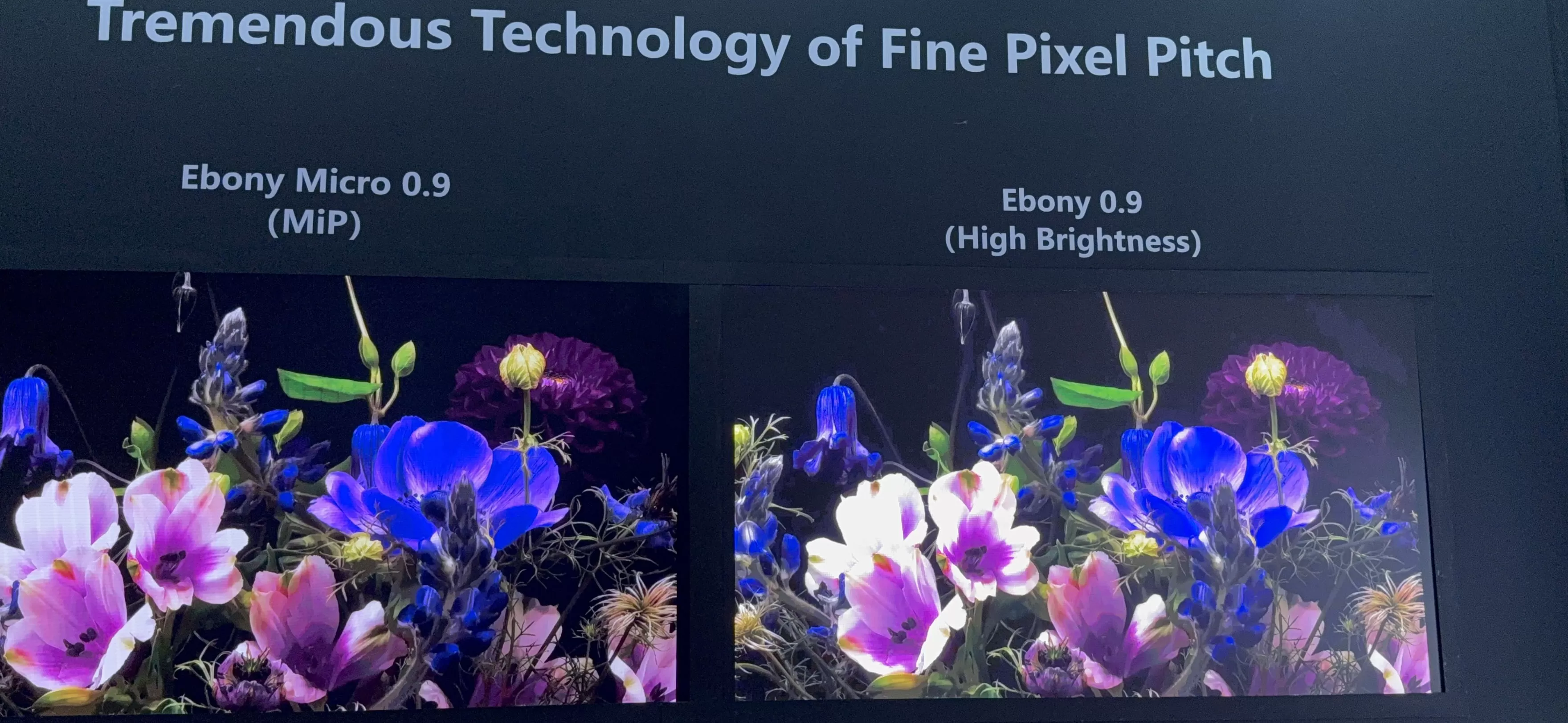

High Brightness for Options

High Brightness for Options1.The larger chip was utilized in Ebony.

2.There is a layer of film on the surface of COB, which is removed with new process. But it still can be assured the fidelity to original color. -

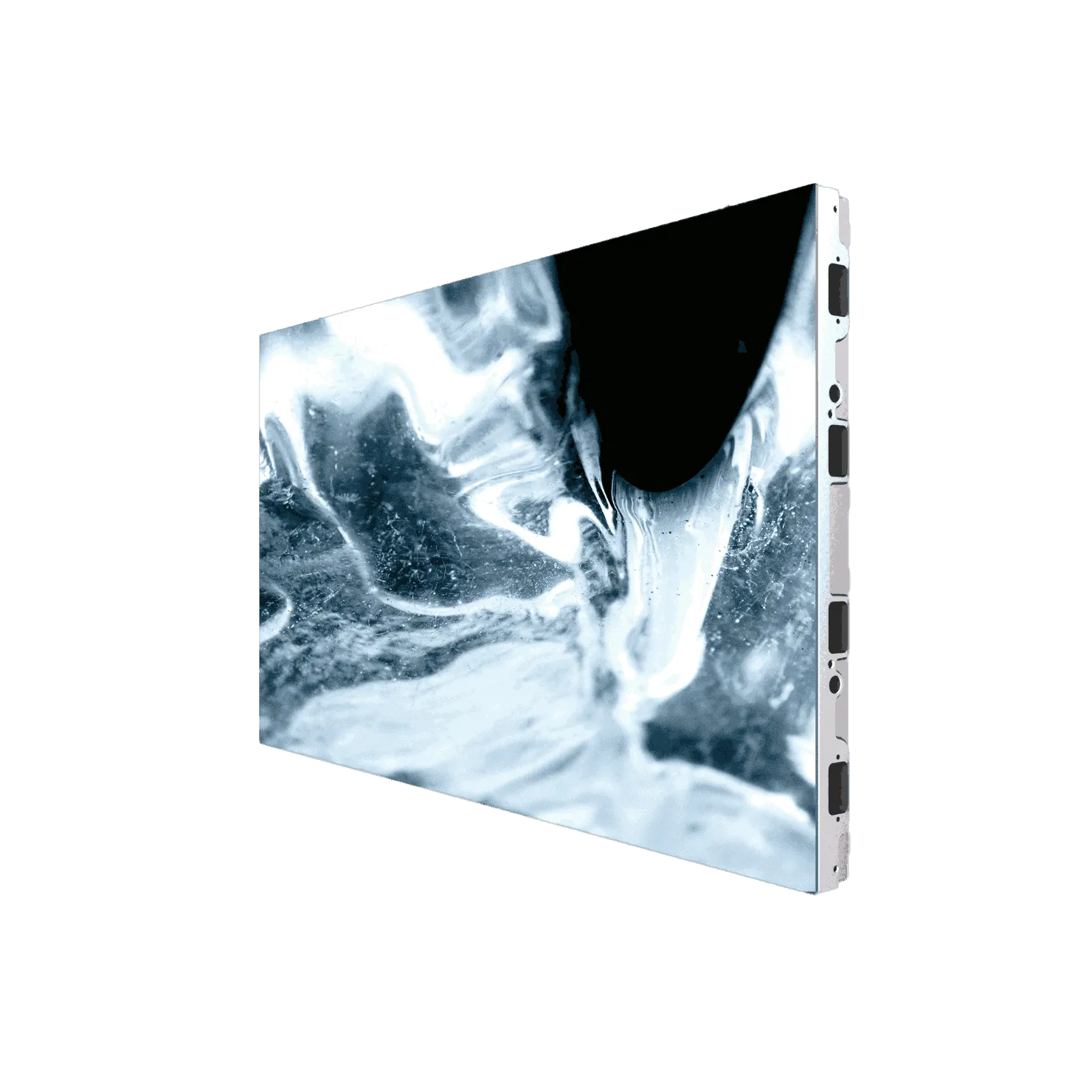

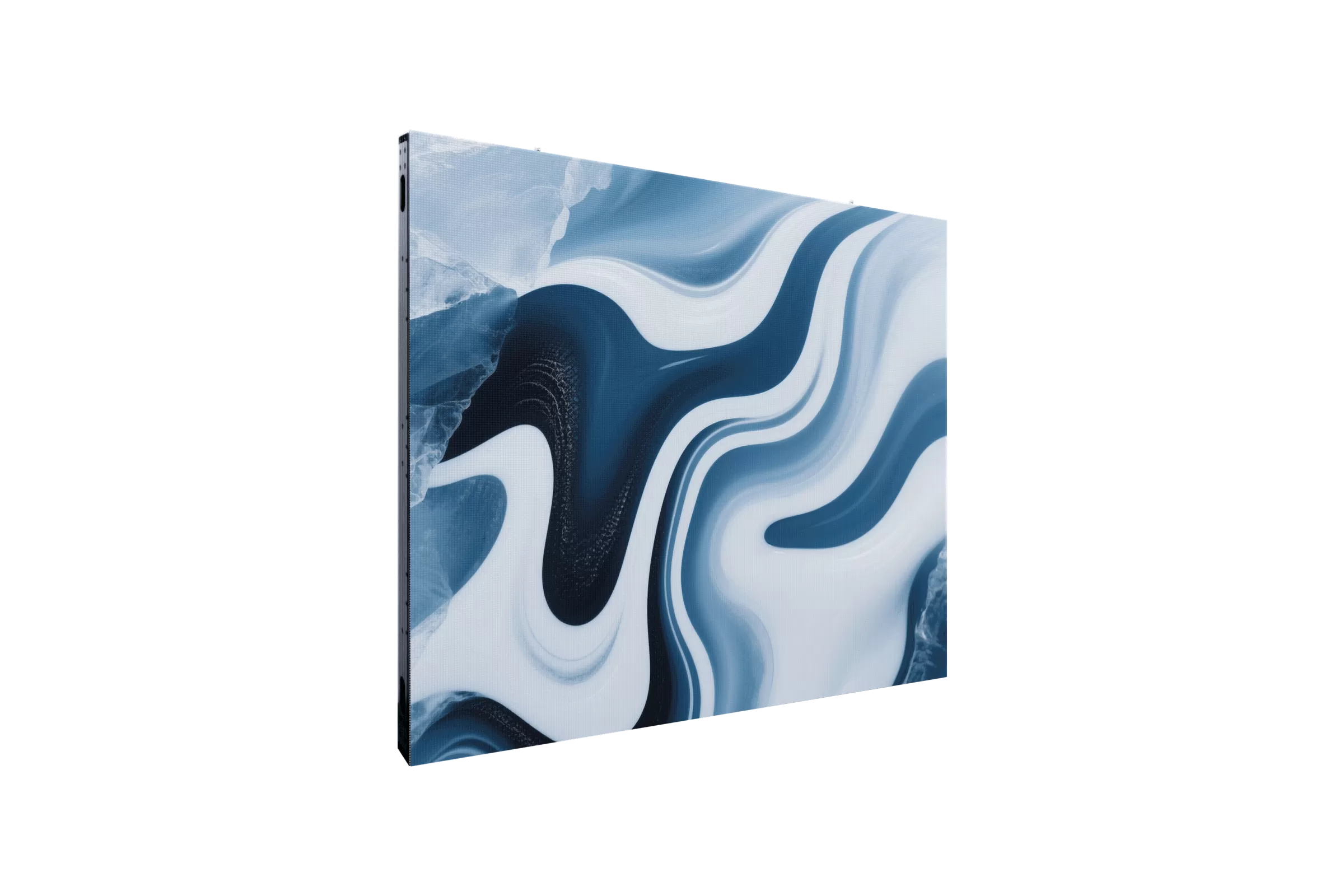

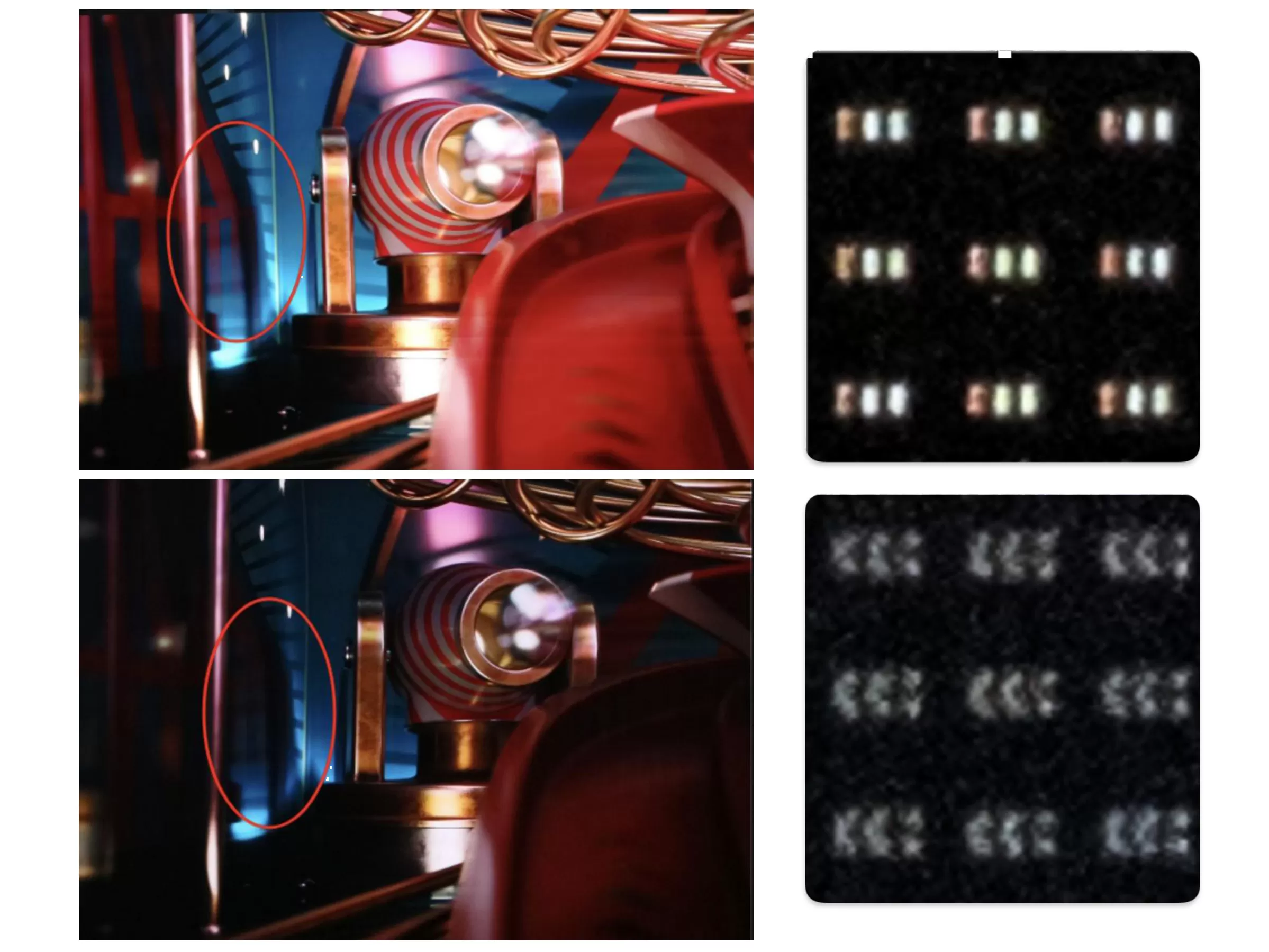

Color Reducibility

Color Reducibility1.High brightness 2000cd

Ebony uses a larger chip for greater brightness

2.Color reducibility

Compared with the conventional COB, there is no covering film on thesurface, and the color is more restored to the original color of the chip.

3.High contrast

Multiple correction technology and pure black and highlimit brightness to achieve ultra high contrast -

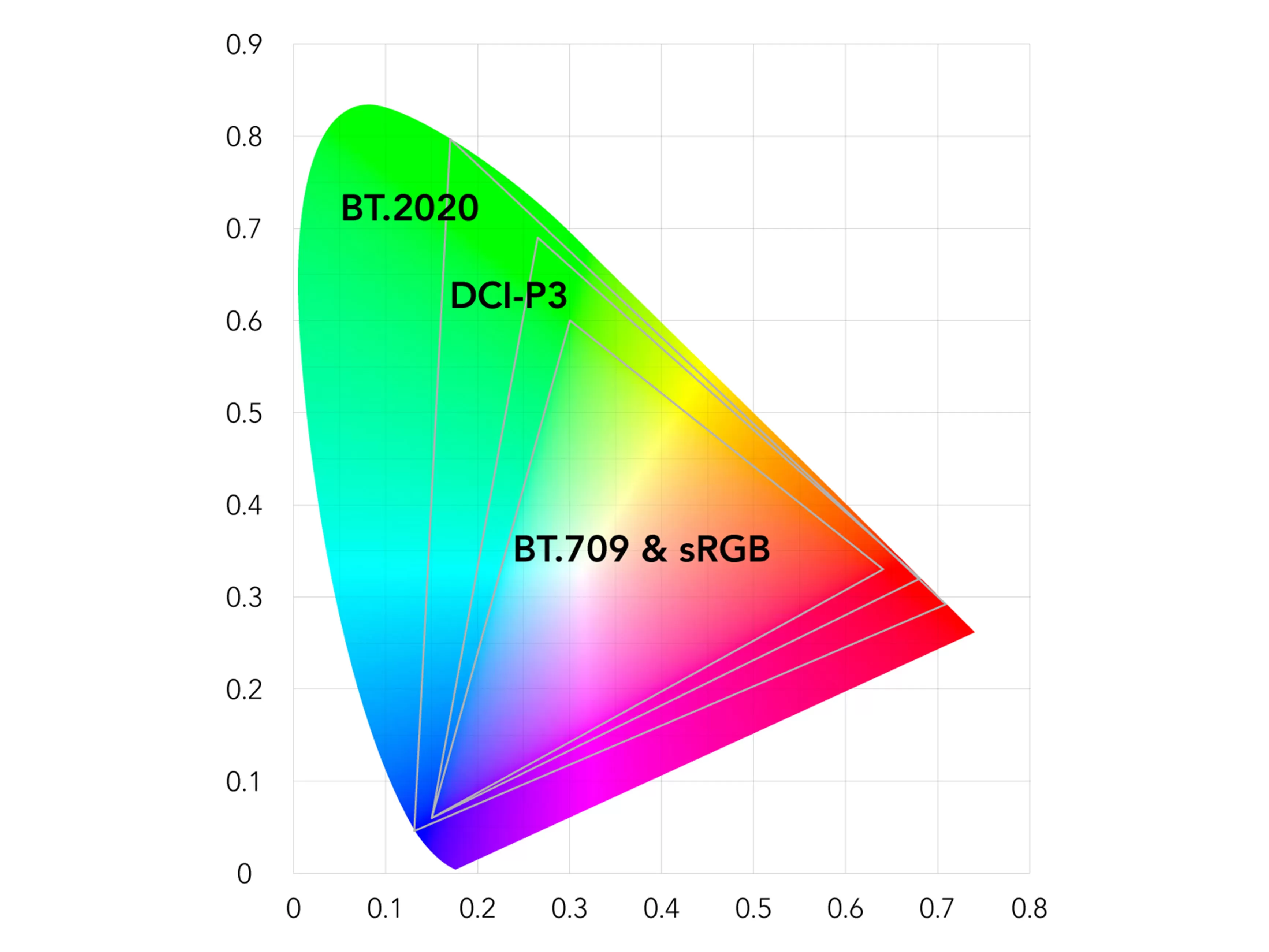

Wide Color Gamut

Wide Color GamutMore than 80% of SHISAI's products use the Rec.2020 (BT.2020) color gamut.

-

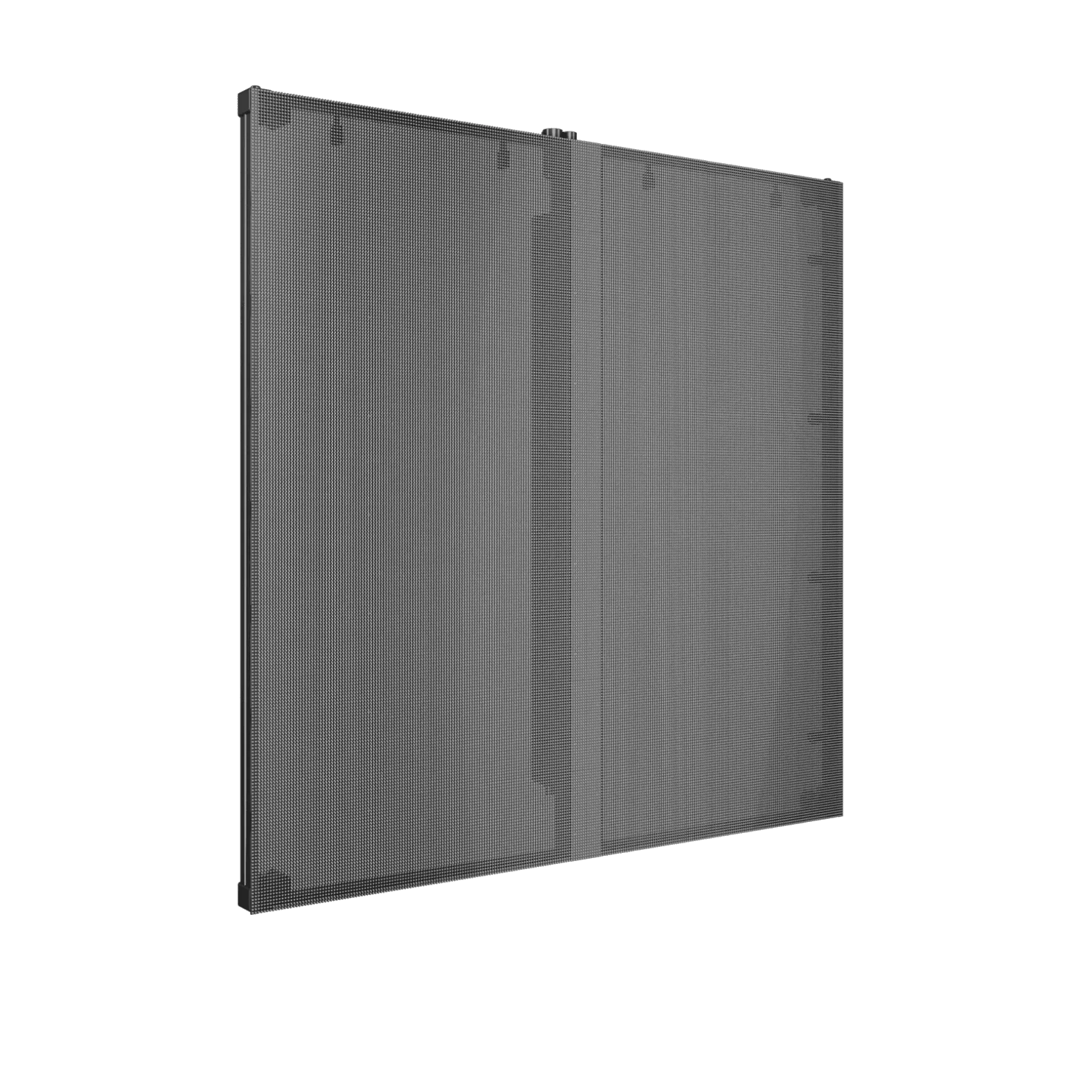

Advantages of COB technology

Advantages of COB technology

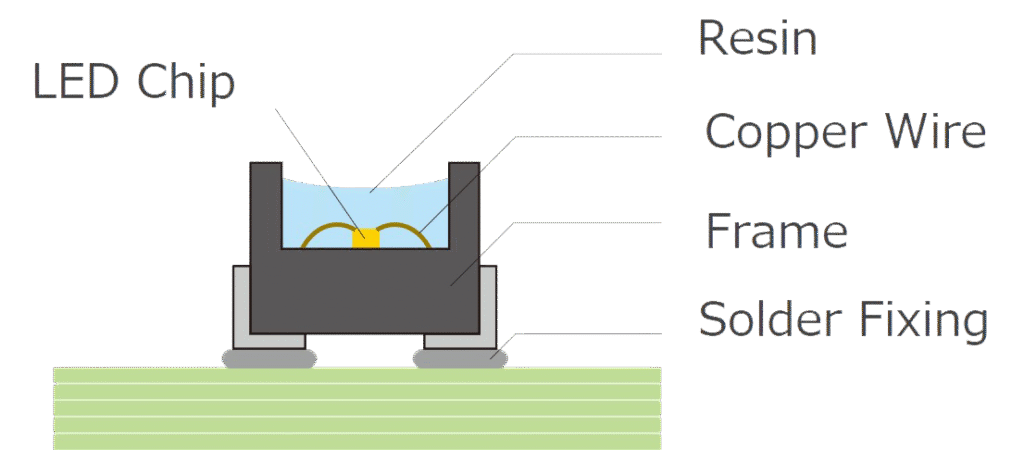

LED Chip Types comparison: COB (flip chip), GOB, SMD

| COB(Frip Chip) | GOB | SMD | |

| Basic structure |

The LED chip is mounted upside down on the PCB without copper wires, resulting in a simple structure with improved convection. |

The surface of an SMD panel product is covered with resin. |

LED components soldered to the circuit board |

| Contrast ratio※1 | Highest | Normal | Low |

| Image quality※2 | Excellent | Normal | Normal |

| Viewing angle※3 | Widest | Normal | Normal |

| Brightness※4 | Highest | Normal | Normal |

| Energy efficiency※5 | Highest | Normal | Normal |

| Durability※6 | ◎ | ◎ | △ |

| Heat dissipation※7 | Best | Normal | Good |

| Failure rate※8 | <5ppm | <25ppm | <50ppm |

| Applicable pixel pitch | ≤ 0.4mm | ≤ 1.2mm | ≤ 1.2mm |

| Impact resistance | ◎ | ◎ | × |

| Moisture resistance | ◎ | ◎ | × |

| Cost | High | Normal | Low |

※1:Compared to other flip-chip displays, COB flip-chips have a smaller pad bonding area, creating more space between chips and improving contrast.

※2:Due to the smaller chip size of COB flip-chips, pixel pitches can reach 0.4 to 1.2 mm, enabling finer image quality.

※3: Due to their different basic structure, COB (flip-chip) displays have a relatively wide viewing angle.

※4: Due to their smaller bonding area, COB displays can use larger chips than SMD displays, achieving higher brightness.

※5: COB displays have the voltage required for RGB, while the flip-chip structure reduces current consumption, making them more energy-efficient.

※6:Due to their simple structure, there are fewer process steps leading to defects, resulting in a longer lifespan.

※7:The flip-chip structure has excellent thermal conductivity and low heat generation, dissipating heat directly to the front and back of the PCB, providing excellent heat dissipation.

※8:Due to their different basic structure, COB (flip-chip) displays have fewer production steps and a lower failure rate.

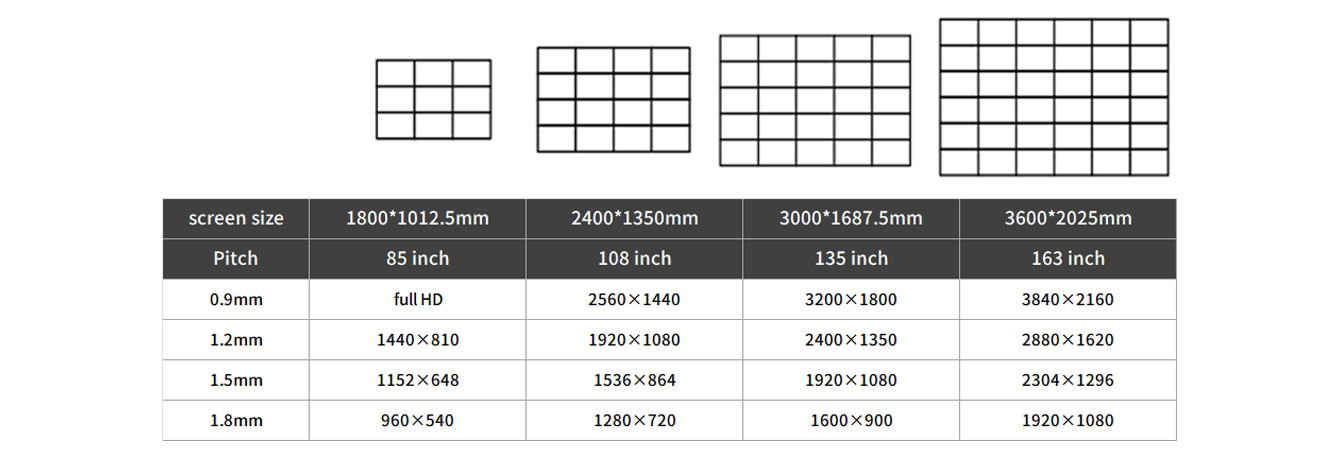

Inch and LED Screen Size

Product Video

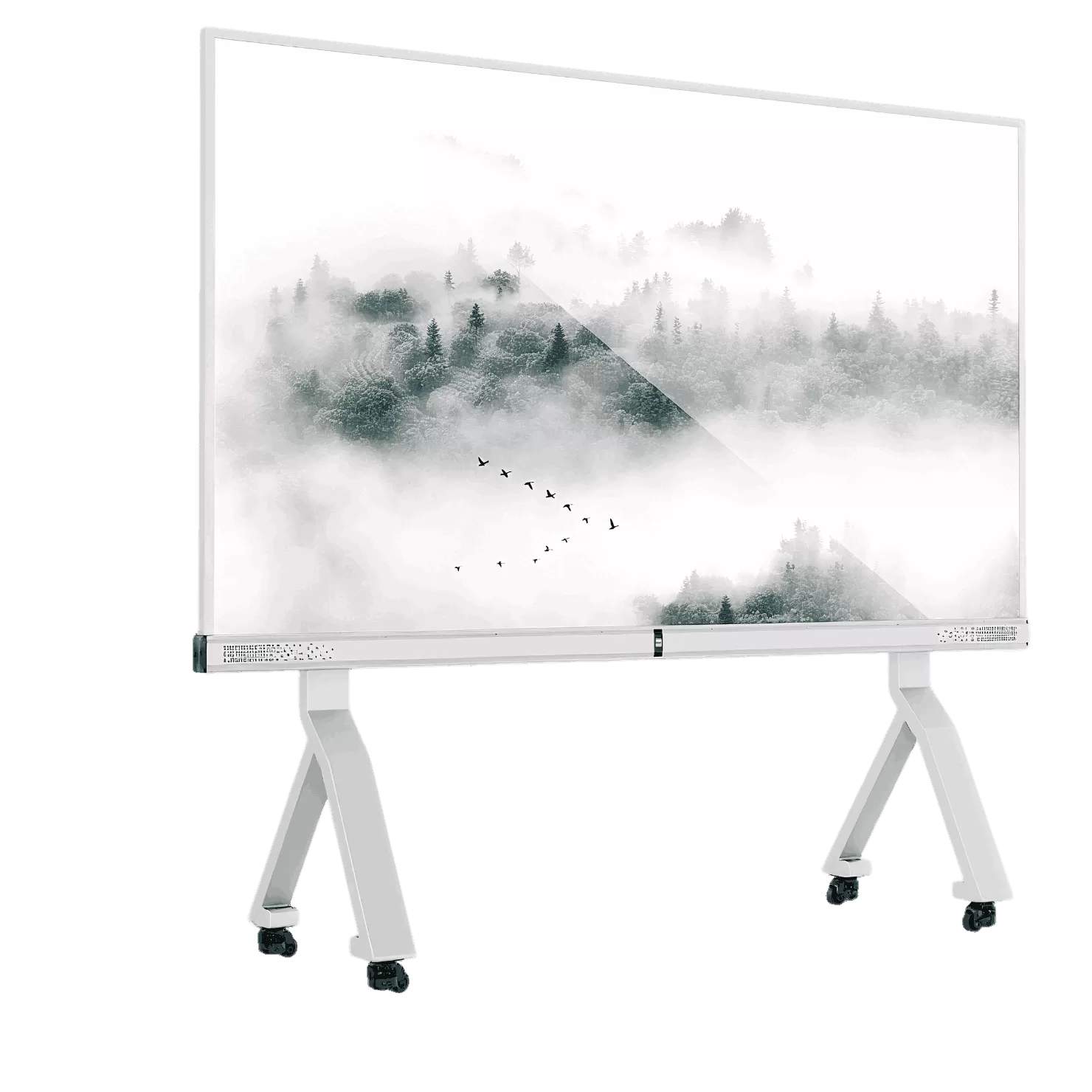

Application Scenario

-

Meeting Room

Meeting Room -

Exhibitions&Museum

Exhibitions&Museum -

Boutique&Brand store

Boutique&Brand store -

Auditoriums&House of worship

Auditoriums&House of worship

Product Parameter

| Ebony | P0.9 | P1.2 | P1.5 | P1.8 |

| COB type | Flip Chip COB | |||

| Pixel Pitch (㎜) | 0.9 | 1.25 | 1.5 | 1.875 |

| Pixel Density (dots/m2) | 1137778 | 640000 | 409600 | 284444 |

| Module Size (㎜) | 150 × 168.75 | 150 × 168.75 | ||

| Module Resolution (dot) | 160 × 180 | 120 × 135 | 96 × 108 | 80 × 90 |

| Panel Size (㎜) | 600 × 337.5 × 29 | |||

| Panel Resolution | 640 × 360 | 480 × 270 | 384 × 216 | 320 × 180 |

| Material | Die-casting Aluminum | |||

| Weight (kg/pcs) | 4.5 | |||

| Brightness (cd/m2) | 1000 / 2000 | 1000 / 1500 | ||

| Viewing Angle (H) | 160° | |||

| Viewing Angle (V) | 160° | |||

| Max Power (W/pcs) | 330 / 650 | 300 / 650 | 300 / 550 | 300 / 550 |

| Avg Power (W/pcs) | 110 / 217 | 100 / 217 | 100 / 183 | 100 / 183 |

| Refresh Rate (Hz) | 3840 | |||

| IP rate | IP 50/20 | |||

| Contrast Ratio | 20000:1 | |||

| Customizaton available | 300 × 337.5 / 600 × 168.75 / 300 × 168.75 | 300 × 337.5 /

600 × 168.75 |

||

| Operating T&H | -10~40℃ & 10 %~80 % RH | |||

| Storage T&H | -20~60℃ & 10 %~85 % RH | |||

| Installation Method | Front & Rear | |||

| Maintenance method | Front | |||

Let’s Keep In Touch

Please leave your needs and requirements, we will

contact you as soon as possible.